ANCEL ANJ600 6-Cylinder GDI Ultrasonic Fuel Injector Cleaner Tester 110/220V Car Motorcycle Ultrasonic Cleaning Auto Tools

SPECIFICATIONS

Brand Name: ANCEL

Origin: Mainland China

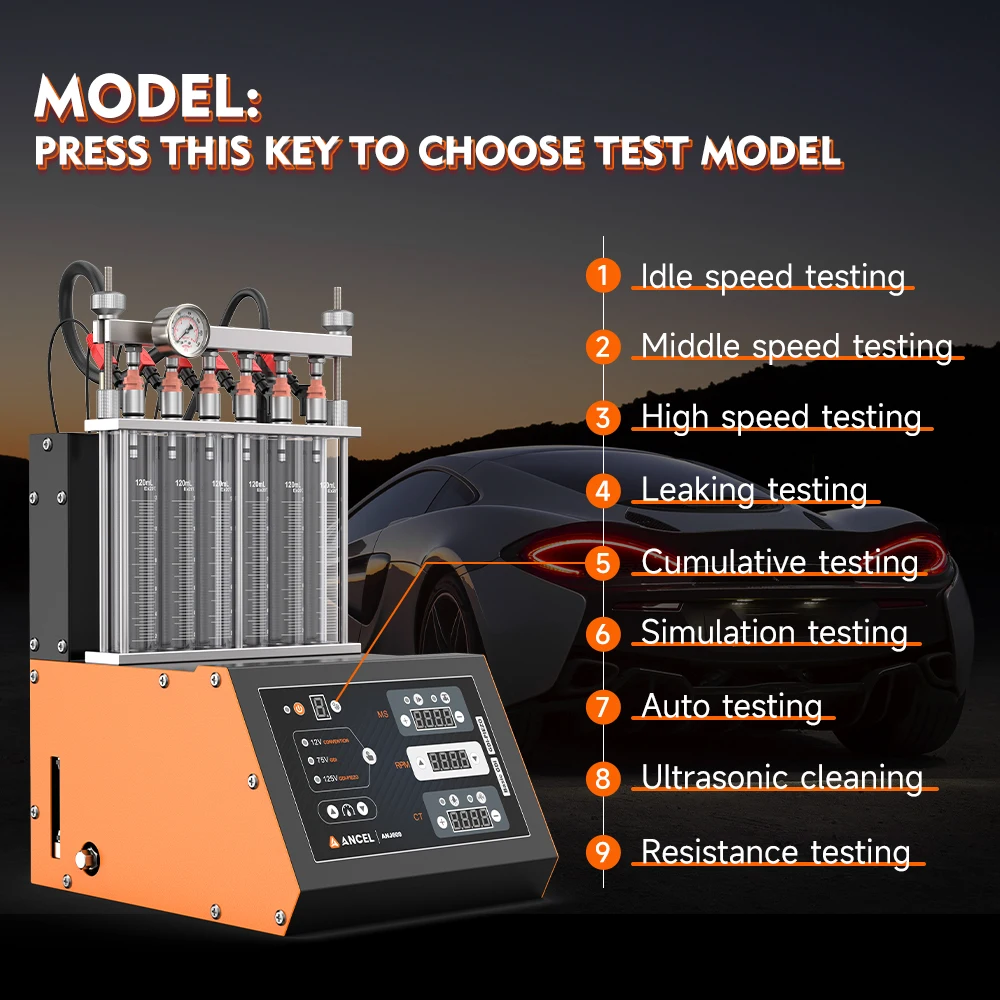

ANCEL ANJ600 For Piezo/Gdi/Conventional Injectors Fuel Injector Tester & Cleaner is a professional 6 cylinders auto fuel injector testing cleaning machine. It is equipped with a pressure gauge which can make the test more precise and easier.Perfectly suit for removing carbon from gasoline cars and motorcycles fuel system, testing leaking, cleaning spark plug, testing injection of injector.

Function Explanation:

1.Ultrasonic Cleaning

Ultrasonic cleaning is to use the penetrating and cavitation shock waves generated when ultrasonic waves propagate in the medium, and powerfully clean objects with complex shapes, cavities and pores to completely remove stubborn carbon deposits on the fuel injector.

2.Injector Testing

This function is to detect the atomization, dripping, blockage, fuel injection angle status of the fuel injectors and the size and balance of the fuel injection of each fuel injector at different speeds.

Main functions:

Ultrasonic cleaning:

To clean injectors to remove the carbon deposition on them completely.

Resistance test:

To test the resistance of fuel injector

Uniformity / Sprayability test:

To test the uniformity of injecting amount of each injector, and to monitor the spraying status of each injector with the help of backlight.

Leakage test:

To test the sealing and dribbling conditions of injectors under system pressure.

Injecting flow test:

To check the injecting amount of the injector in 15 seconds of constant injection.

Working modes test:

To test injectors under different working conditions.

On-Vehicle Cleaning:

Coming with a variety of disassembly-free cleaning connectors, the device can be used to perform on-vehicle cleaning and maintenance for various vehicle models.

Low resistance injectors test function

Through the dedicated motherboard, it supports the full and long test of low resistant fuel injector such as 1 ohm.

Multi items Setting:

Set different parameters of the device, including the buzzer sound level, display brightness, and backlight brightness.

Version information:

to check the software version information of the current device.

Cleaning & testing sequences

Recommended to carry out the complete cleaning and testing procedures as the following order.

● Ultrasonic cleaning;

● Uniformity / Sprayability test;

● Leakage test;

● Injecting flow test;

● Working modes test.

* Resistance Test.

1) Connect one end of the resistance measurement line to the interface on the right side of the device, and the other end to the two electrodes of the fuel injector.

2) Start the machine, and press the key. The resistance value will be displayed on the screen.

3) If needed, measure several times to confirm the measured value.

4) After the measurement is completed, remove the fuel injector and the resistance measurement line

* Ultrasonic Cleaning

It works by sending an ultrasonic vibration signal to the injector through the pulse signal cable, which causes a strong vibration of the carbon inside and thus enables more thorough cleaning.

Procedures

1) Place the injector/pump which has gone through surface cleaning in the launder.

2) Add enough injector detergent into ultrasonic cleaner so that the liquid level is about 20mm above the needle valve of injectors / whole pump.

3) Plug the pulse signal wire to injector / pump respectively.

4) Select ultrasonic cleaning function and then set the time.

5) Press RUN key to start the procedure.

6) Turn on the ultrasonic cleaning switch on the left side of the machine.

7) When the time is up, it will stop automatically as the beeper rings.

8) Turn off the ultrasonic cleaning switch on the left side of the machine after cleaning procedure.

9) Take the injector / pump out of the launder and wipe them with a dry soft cloth. Get ready for next operation.

* Uniformity/Sprayability Test

Uniformity test is to find out the difference of the injectors injecting at the same working condition. This test can indicate the comprehensive influences on the injector caused by electrical nature, bore variation and clogging. Spray

ability test is to inspect the spraying performance by observing the injectors.

Installing and testing procedures for injectors

1) Choose a proper adaptor according to the injector type and mount it to the fuel separator.

2) Install the injectors in forward direction (Apply a little lubricating grease on the O-ring.)

3) Install the fuel separator with injector onto the plate of the test tube.

4) Connect the injector pulse signal wire.

5) Before doing this test, drain the test liquid from the measuring cup if there is any.

6) Select Uniformity/Sprayability test function, set corresponding parameters (consult the appendix for pressure setting, consult vehicle manuals for other parameters as needed), and then press RUN key to start the test.

7) When the test is completed, the equipment will auto stop with the ring of the buzzer.

Leakage Test

Leakage test is to inspect the sealing conditions of the injector needle valve under system pressure and to find out if the injector is dribbling

Procedures

Installation refer to Uniformity/ Sprayability Test.

1) Before doing leakage test, please drain the rudimental residual test liquid from the measuring cup.

2) Select Leakage Test function and press Run key to start. At this time the system pressure can be adjusted by pressing + and – key to observe dribbling from the injector the pressure is adjusted preferably 10% higher than manufacturer’s specifications.

3) When the test is over, the equipment will automatically stop and the buzzer will ring simultaneously.

Injecting Flow Test

Injecting flow test is to check if the injecting flow in 15 seconds meets the specifications for injecting amount. The deviation reflects the wear or clogging in the injector, instead of electrical parameter variation.

Procedures:

Installation refer to Uniformity/ Sprayability Test.

1) Before the test, drain all the test liquid in the measuring cups if there is any.

2) Select Modes function and choose the mode needed , then press Run key to start the test.

3) Adjust the fuel pressure by pressing + or – keys.

4) When the test is over, the equipment will auto stop at the ring of the buzzer.

Working modes test

Working modes test contains three working status simulation tests(Acceleration, Deceleration, Acceleration+ Deceleration test)). This function can test more comprehensive performance of injectors by simulating the various engine working conditions.

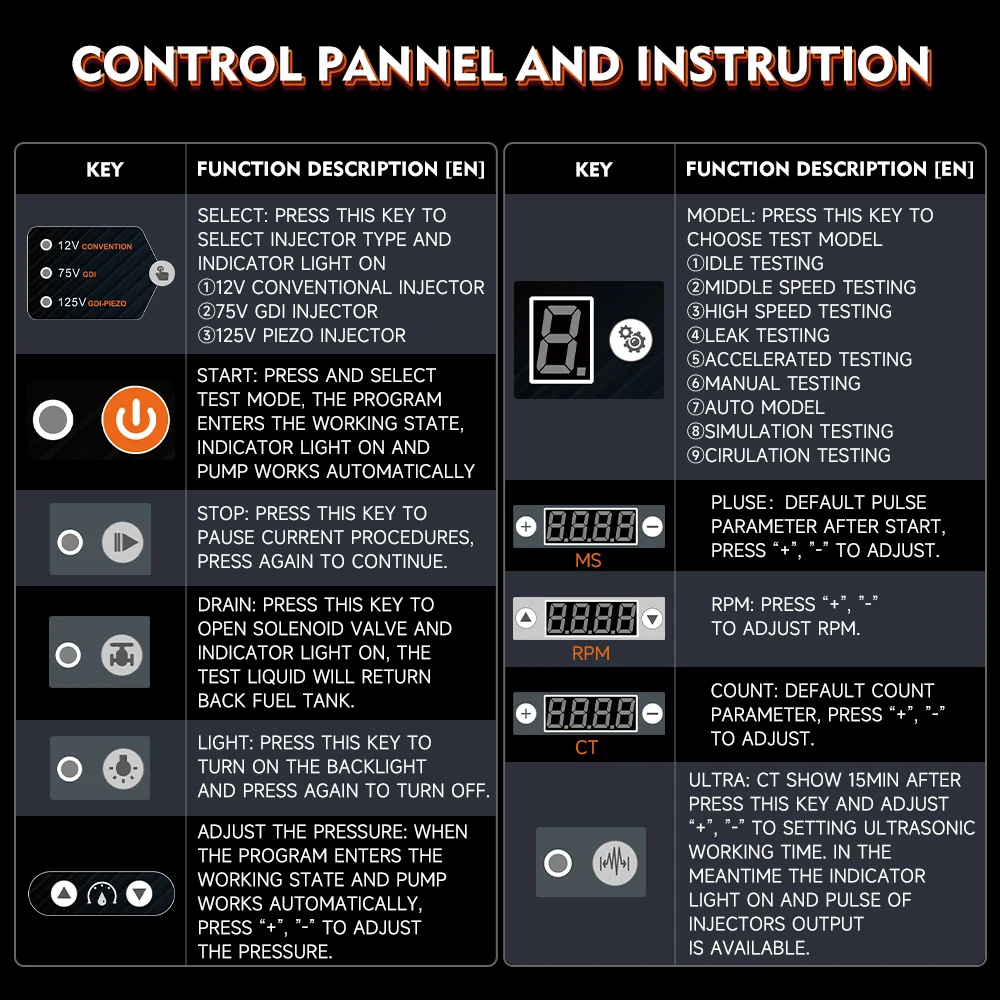

Friendly control panel

Smart Control Panel

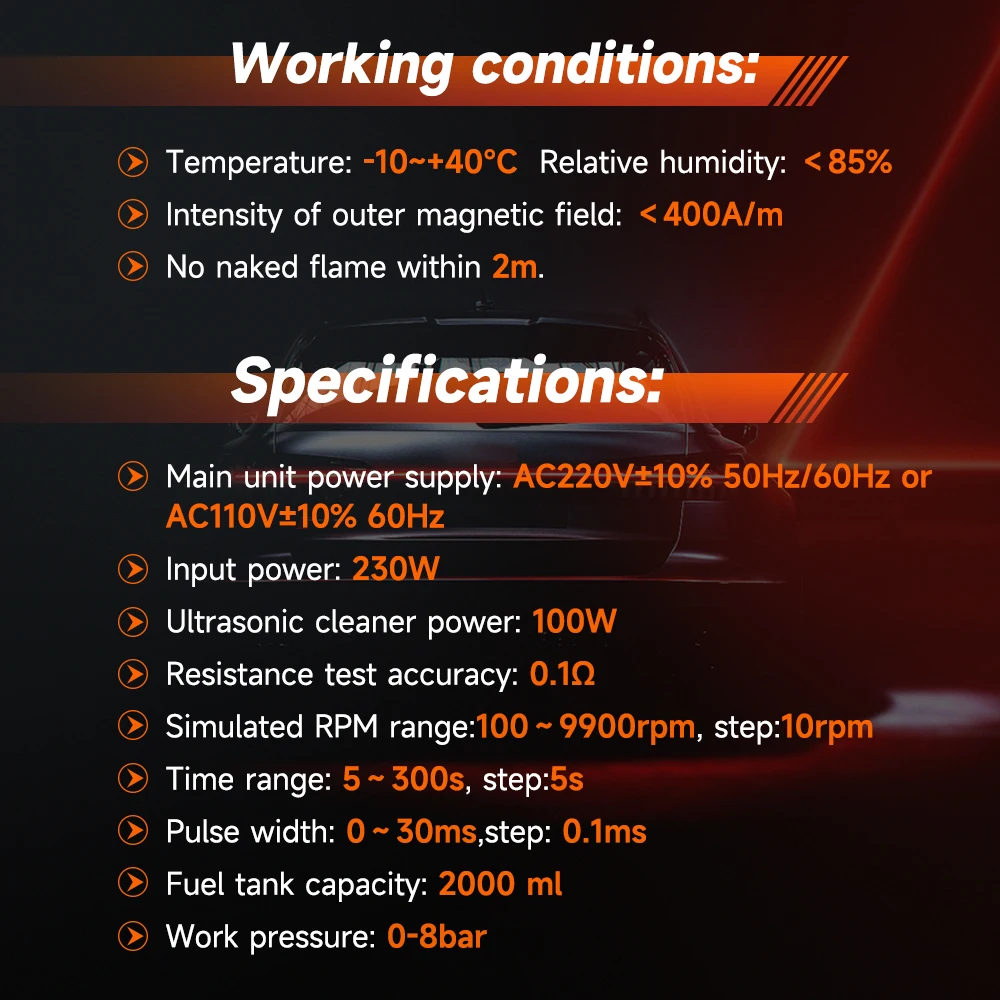

Working conditions:

Temperature: -10~+40℃ Relative humidity: <85%

Intensity of outer magnetic field: <400A/m

No naked flame within 2m.

Technical parameter

Main unit power supply: AC220V±10% 50Hz/60Hz or AC110V±10% 60Hz

Input power: 230W

Ultrasonic cleaner power: 100W

Resistance test accuracy: 0.1Ω

Simulated RPM range:100~9900rpm, step:10rpm

Time range: 5~300s, step:5s

Pulse width: 0.1~30ms,step: 0.1ms

Fuel tank capacity: 2000 ml

Work pressure: 0-8bar